Train paths and line inspections

It is necessary for the railroad companies to watch over their tracks to ensure their safe and economical work. All possible malfunctions may be cost generating and could tarnish the company’s image. Because of the huge railway lines’ networks spreading throughout thousands of kilometers, their monitoring is not easy. Traditionally, planes and helicopter are used which are cost generating. With UAV we can inspect huge sections of the railway tracks and ensure a detailed monitoring in real time. Such solutions lead to defects and accidents detection.

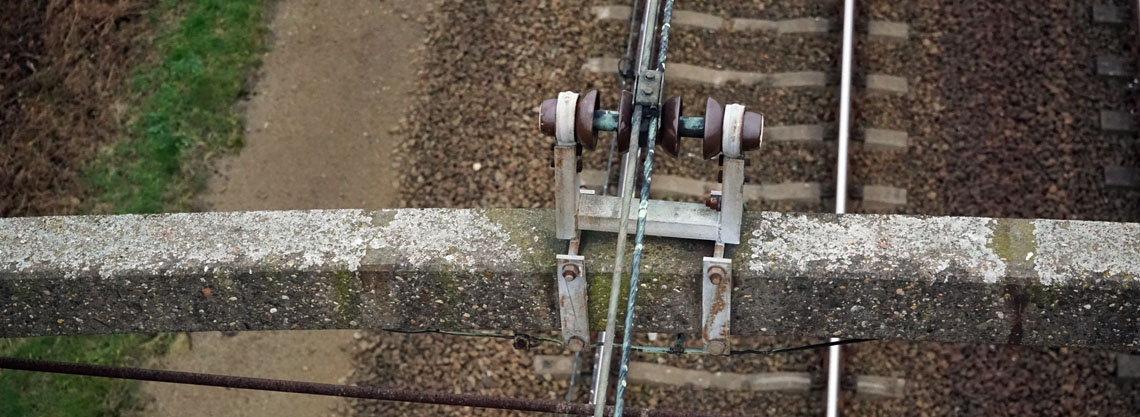

Our drones are equipped with devices which enable making extremely precise aerial images . It is a key feature in railroad tracks inspection where UltraHD 4K camera images can provide you with the comprehensive and complete mapping of the inspected object’s technical condition. We have a live coverage which allows for the immediate detection of all malfunctions and, as a result, reduces costs.

Why choose us?

- Railroad tracks and poles inspection throughout Europe,

- UltraHD 4K video image quality with live video feed,,

- Recording the video material from the conducted inspection for further analysis,

- Image analysis conducted by a trained team of engineers,

- In case of emergency, thanks to our fleet of planes and helicopters we are able to get to any location in Europe within a few hours.

Drone inspection advantages:

- Safety – UltraHD 4K quality up close image without a man’s presence onto the poles or railroad tracks,

- Cost saving – Drone inspection is cheaper than using a helicopter while also maintaining the same image quality,

- Time saving – The system’s mobility and its ability to rapidly analyse gathered data reduces the time of defect detection and repair to a minimum,

- High productivity– Low costs and short time of taking photos make for the most effective way of the railroad tracks’ inspection,

- High quality inspection– our trained pilots are able to fly very close to the inspected object. Together with our engineers’ knowledge, we can rapidly locate and diagnose the problem.

Drone inspection disadvantages:

- Short flying time – short flying time due to low battery durability requires coming back to the starting point every 15-25 minutes. However, we have a lot of batteries as well as a mobile recharging station to ensure the consistency of inspections,

- Weather restrictions – considering relatively low weight of the drone and considerable amount of electronic elements we must not fly when the wind’s speed exceeds 18 m/s, when it’s raining or snowing.

EN

EN  PL

PL NO

NO