Solar panels inspections (photovoltaic systems)

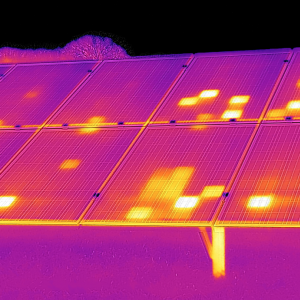

Photovoltaic panels are highly sensitive to external agents and must be regularly inspected and diagnosed in order to efficiently generate electricity. Thermography is the ideal method for inspecting and diagnosing photovoltaic panels. It helps to determine the temperature decomposition and allows for detection of overheated areas in individual cells or all of the module cells. The hot spots results from shading as well as transport or production defects.

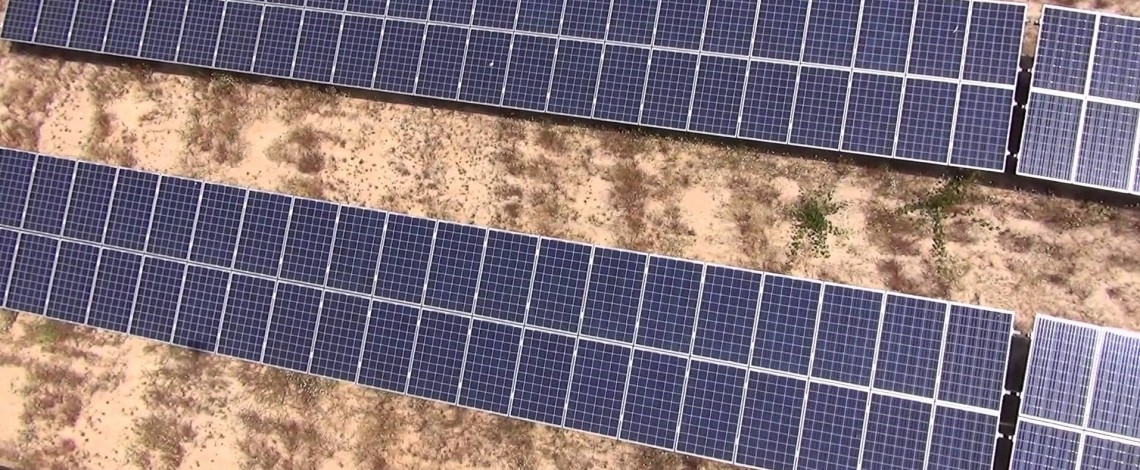

Standard ground handling inspection cannot provide us with the image of the entire tested object but  only its fragments. Drones’ flights can be programmed according to our needs. Additionally, using the thermal imaging cameras integrated with a GPS system, we are able to acquire an accurate map of the area together with spacial temperature distribution.

only its fragments. Drones’ flights can be programmed according to our needs. Additionally, using the thermal imaging cameras integrated with a GPS system, we are able to acquire an accurate map of the area together with spacial temperature distribution.

Our drones are equipped with devices which enable making extremely precise aerial measurement . It is a key feature in photovoltaic panels inspection where the combination of thermal camera and UltraHD 4K camera images can provide you with the comprehensive and complete mapping of the inspected object’s technical condition.

Why choose us?

- Thermographic inspection of the solar power stations throughout Europe,

- UltraHD 4K video image quality with live video feed,,

- Highest quality FLIR brand thermal camera images,

- Mapping of the area with spacial temperature distribution,

- Recording the video material from the conducted inspection for further analysis,

- Image analysis conducted by a trained team of engineers,

- In case of emergency, thanks to our fleet of planes and helicopters we are able to get to any location in Europe within a few hours.

Drone inspection advantages:

- Time saving – The system’s mobility and its ability to rapidly analyse gathered data reduces the time of defect detection and repair to a minimum,

- High productivity– Low costs and short time of taking photos make for the most effective way of the photovoltaic panels’ inspection,

- High quality inspection– our trained pilots are able to fly very close to the inspected object. Together with our engineers’ knowledge, we can rapidly locate and diagnose the problem,

- The best thermal imaging equipment – using highest quality thermal imaging cameras we are able to detect defects arouse during transportation, storage or production.

Drone inspection disadvantages:

- Short flying time – short flying time due to low battery durability requires coming back to the starting point every 15-25 minutes. However, we have a lot of batteries as well as a mobile recharging station to ensure the consistency of inspections,

- Weather restrictions – considering relatively low weight of the drone and considerable amount of electronic elements we must not fly when the wind’s speed exceeds 18 m/s, when it’s raining or snowing.

EN

EN  PL

PL NO

NO